How to Thread a Sewing Machine: A Beginners Guide – Part 1

Threading a sewing machine can feel a bit daunting at first, but it quickly becomes second nature after you’ve done it a couple of times. These days, I don’t even think about it—muscle memory just takes over.

That said, writing this tutorial made me slow down and walk through each step more deliberately. It reminded me just how intuitive the process becomes with a little practice.

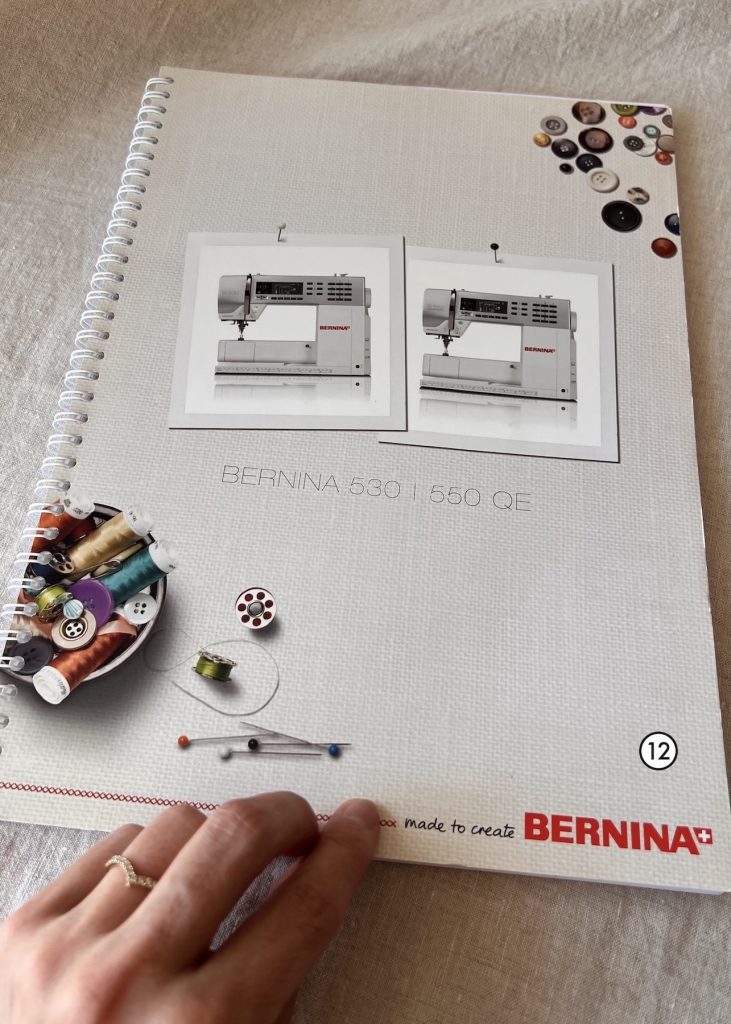

To demonstrate how to thread a sewing machine, I’ll be using my Bernina B530. Even if your machine looks different—say, if your bobbin loads from the top instead of the front—the basic process is usually quite similar. You may just need to adjust one or two steps depending on the model.

This tutorial turned out to be a bit more involved than I initially expected, and I wanted to include plenty of photos to help along the way. So, I’ve broken it into two parts:

- Part 1 covers the basics: tools and equipment, the anatomy of a sewing machine (as it relates to threading), how to wind and insert a bobbin, and how to thread the upper thread of your machine.

- Part 2 will dive into some more specific processes: changing the needle and presser foot, using specialty needles (such as twin needles), and troubleshooting common thread tension issues.

What You’ll Need

First things first. Let’s gather some tools and equipment.

1. Good quality thread. I recommend brands like Gutermann, Mettler, or Amann Rasant. It really does make a difference to the stitch quality and they are better for the machine.

2. Bobbin(s)

3. Bobbin case

4. Presser foot

5. Needles. These will depend on your fabric and the needs of your project. If you need some help deciding, check out the article ‘Understanding Sewing Machine Needles’.

6. Scissors or thread snips

7. Scrap fabric. Preferably the same fabric you’ll be using for your project.

Optional extras:

8. Foam pad(s)

9. Spool disc(s)

10. Screwdriver

11. Tweezers

12. Sewing machine manual. It’s always useful to keep this nearby. Even if you think you know your machine well, reviewing the manual can reveal some helpful features or tips you may have missed. I recently revisited mine and discovered functions I didn’t know existed even after 12+ years of having my machine!

If you don’t have a physical copy, check the manufacturer’s website as many offer free PDF versions.

Tip: Before starting any new project, I like to take a few minutes to give my machine a quick clean and oil—especially around the bobbin area. A small brush and a lint-free cloth work well for removing dust and fluff. While you’re at it, pop in a fresh needle. These small habits don’t take long, but they make a big difference to both your sewing machine’s performance and the quality of your projects.

Understanding the Different Parts of a Sewing Machine

Sewing machines will differ slightly from model to model, but this guide will hopefully offer a solid starting point. I’ve focused on the key components involved in threading and features you’ll find on most, if not all, sewing machines.

Front view:

13. Bobbin cover

14. Stitch plate

15. Reverse button

16. Thread take-up cover

17. Thread take-up lever

18. Stitch width

19. Needle position

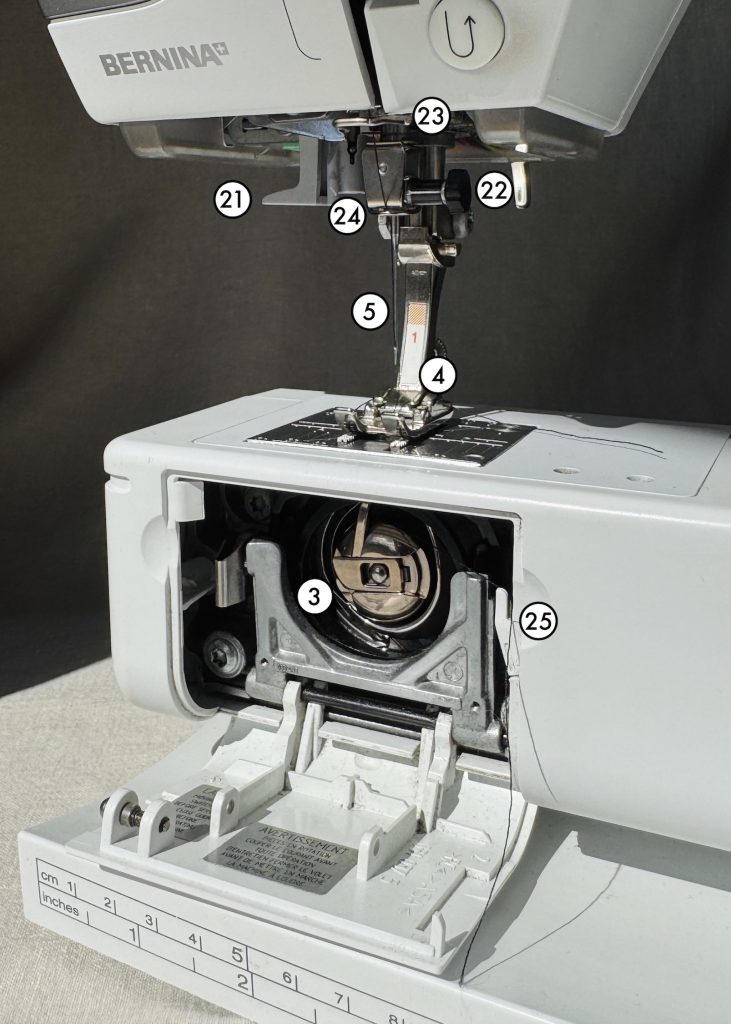

Close up front:

21. Automatic needle threader

22. Needle clamp

23. Upper thread guide

24. Lower thread guide

25. Thread cutter (bobbin cover)

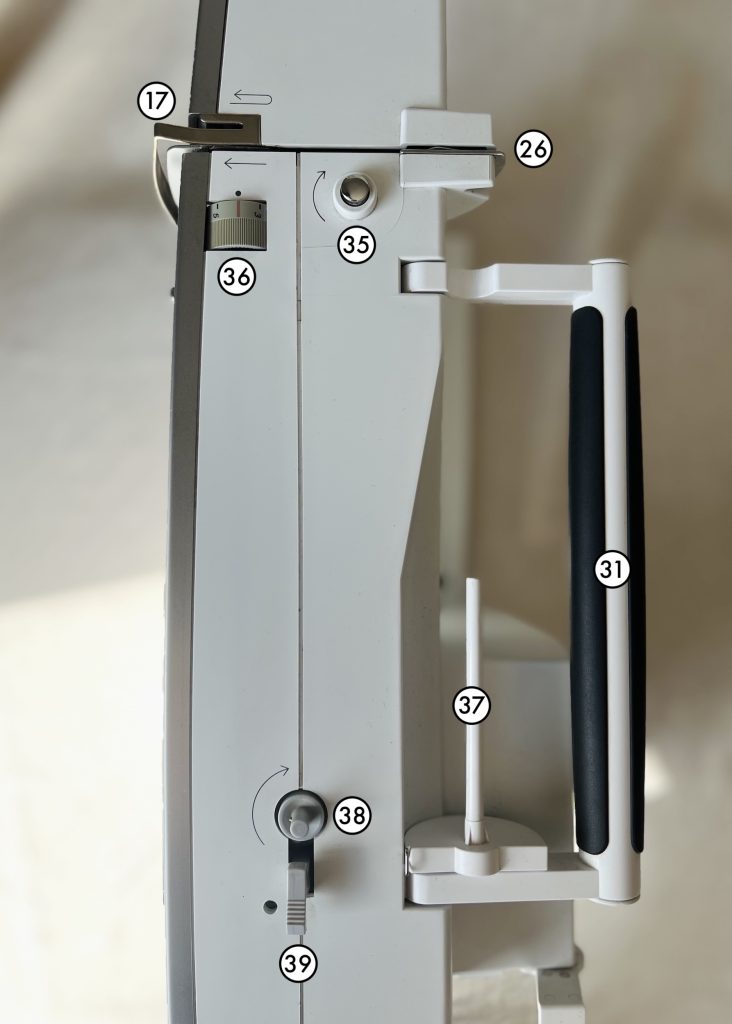

Left side:

26. Rear thread guide

27. Presser foot pressure adjustment wheel

28. Thread cutter (rear)

29. Presser foot lifter

30. Presser foot clamping lever

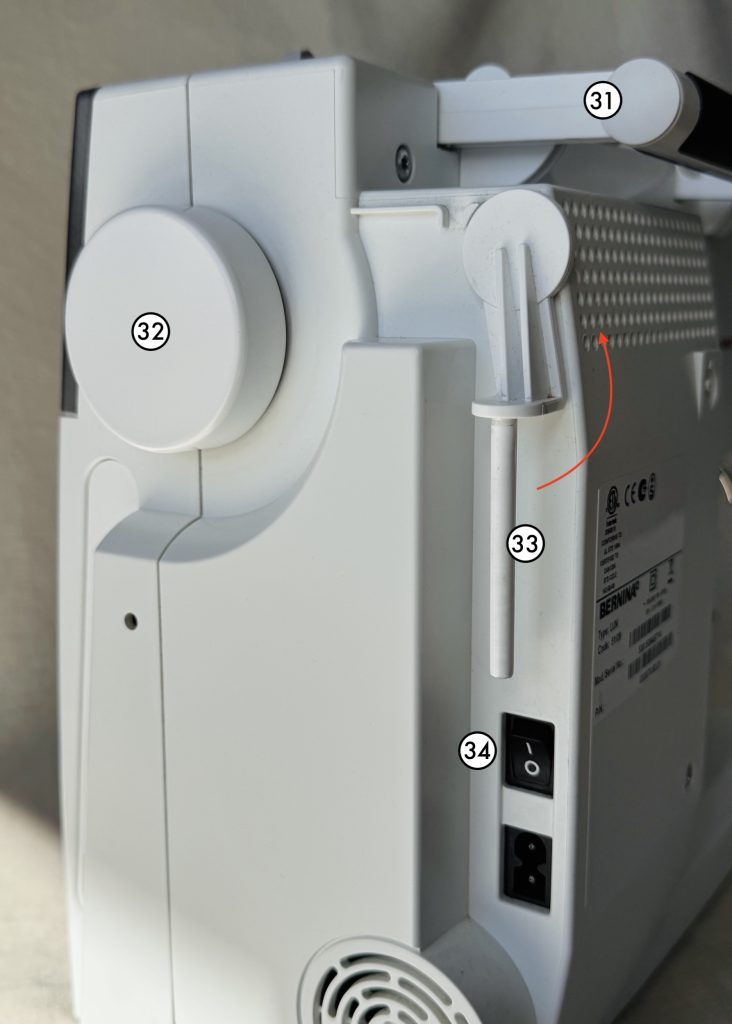

Right side:

31. Carrying handle

32. Hand wheel

33. Vertical spool pin

34. Power button

Top view:

35. Bobbin winder pre-tension

36. Thread tension adjustment wheel

37. Horizontal spool pin

38. Bobbin winder device

39. Engaging lever and thread cutter (bobbin)

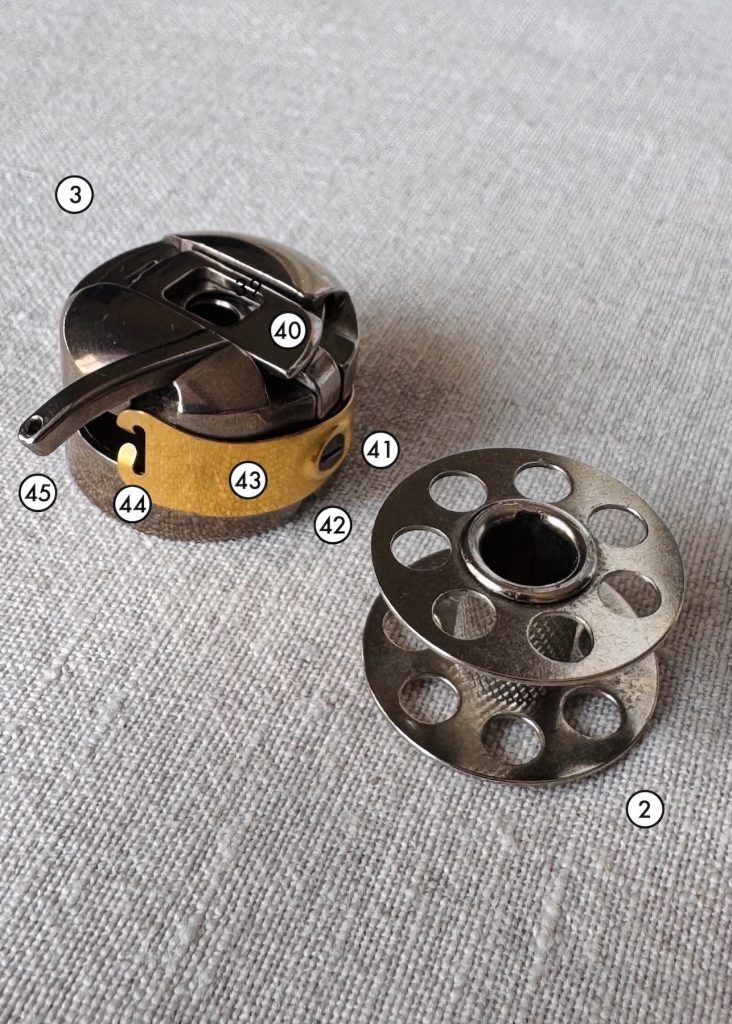

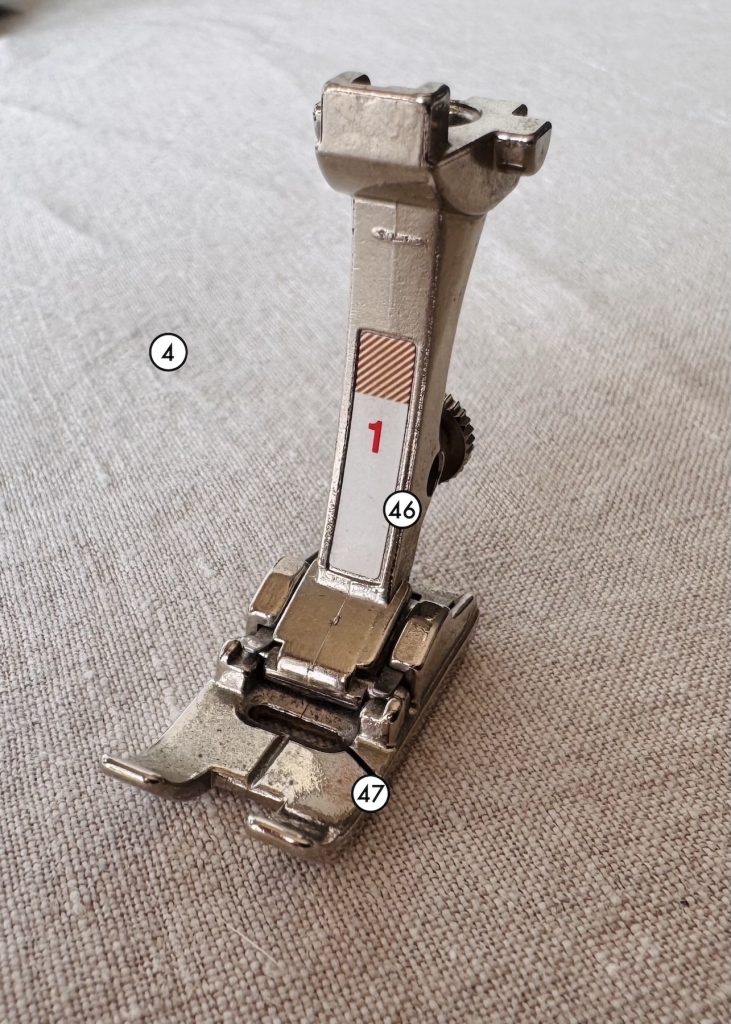

Extra bits and bobs:

40. Latch

41. Tension screw

42. Slot

43. Tension spring

44. T-shape slit

45. Finger

46. Peg

47. Sole

How to Thread a Sewing Machine

For safety, I highly recommend keeping the sewing machine turned off during most of the threading process. The only exception is when winding the bobbin, which requires the machine to be on. Trust me, I’ve lost count of how many times I’ve accidentally pressed down on the foot pedal while threading. Keep those fingers safe!

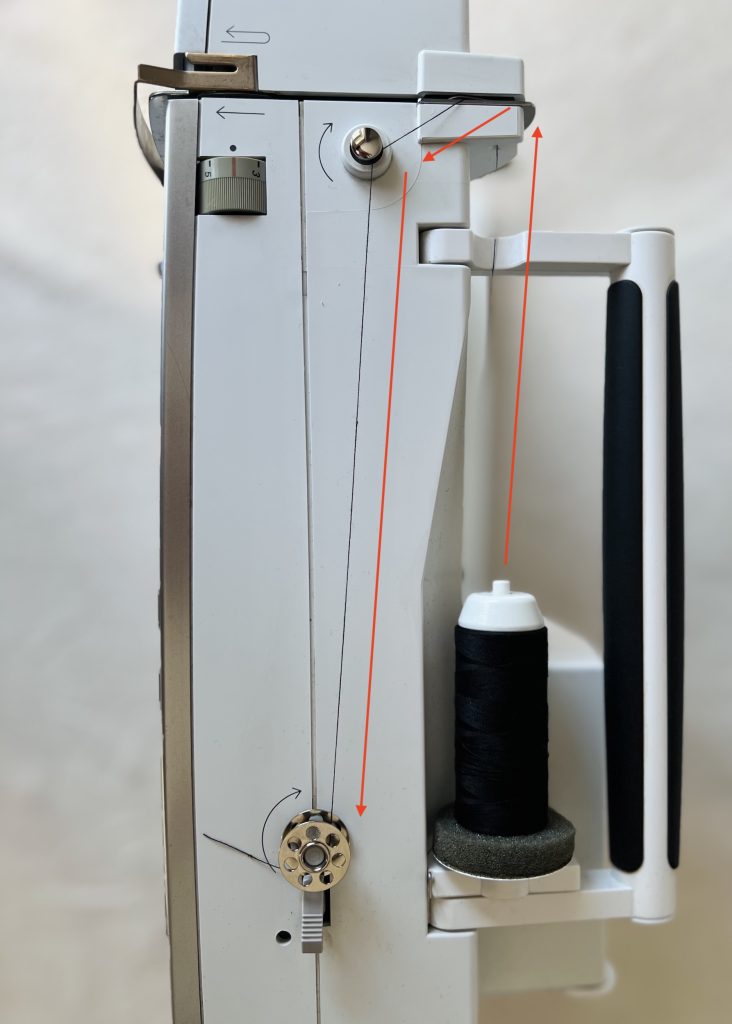

Winding the bobbin

1. Place a foam pad onto the horizontal spool pin, followed by the spool of thread. Attach a spool disc on the end to prevent the thread from sliding off. Ensure that the thread unwinds in a clockwise direction.

Note: You can also use the vertical spool pin in the same way. This is sometimes simply a matter of personal preference.

2. Place an empty bobbin onto the bobbin winder device.

2. Place an empty bobbin onto the bobbin winder device.

3. Feed the thread through the rear thread guide, and around the bobbin winder pre-tension.

4. Wind the thread around the bobbin 2–3 times in a clockwise direction.

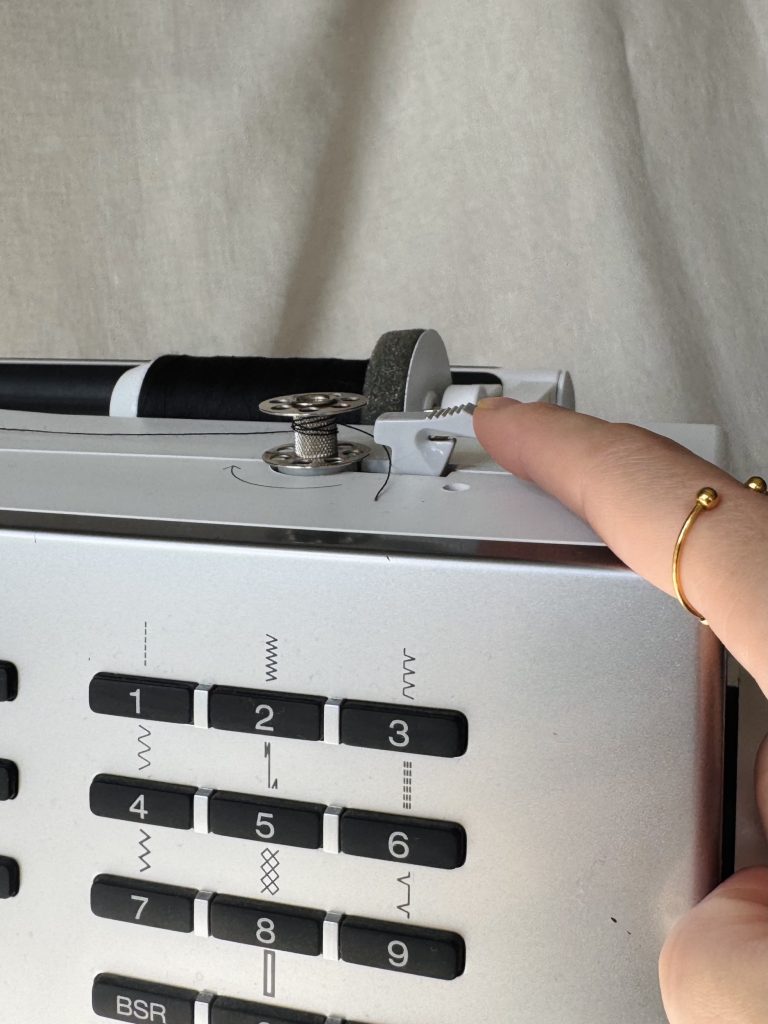

5. Push the bobbin engaging lever towards the bobbin. The bobbin should start to wind automatically, stopping when the bobbin is full.

6. Remove the bobbin and cut the thread using the bobbin thread cutter.

Threading the upper thread

1. Raise the needle by turning the hand wheel.

2. Raise the presser foot by lifting the presser foot lifter at the back of the machine.

3. Position the spool of thread either on the horizontal or vertical spool pin (as per Step 1 of winding the bobbin).

4. Feed the thread through the rear thread guide, and toward the front right of the machine.

5. Feed the thread downward through the right of the thread take-up cover and around, before going back up through the left of the thread take-up cover.

6. Feed the thread through the thread take up lever.

7. Feed the thread down through the thread guides.

8. Thread the needle and pull the thread through the slit of the presser foot and towards the back of the machine.

9. Cut off any excess thread length using the rear thread cutter.

Note: Check whether your machine has an automatic needle threader. On my machine, there is a pull down lever positioned to the left of the needle.

Tip: If you want to change the thread but don’t want to unthread the machine completely simply cut the end of the existing thread at the thread spool. Replace the thread spool with the new thread and tie the ends together. Trim the thread tail. Gently pull the old thread through the machine, pulling the new thread along with it. Cut the thread near the eye of the needle and pull through the old thread. Rethread needle with new thread. This method also works well on an overlocker too (check out the article ‘How To Re-thread an Overlocker (The Easy Way)’ for more on this.

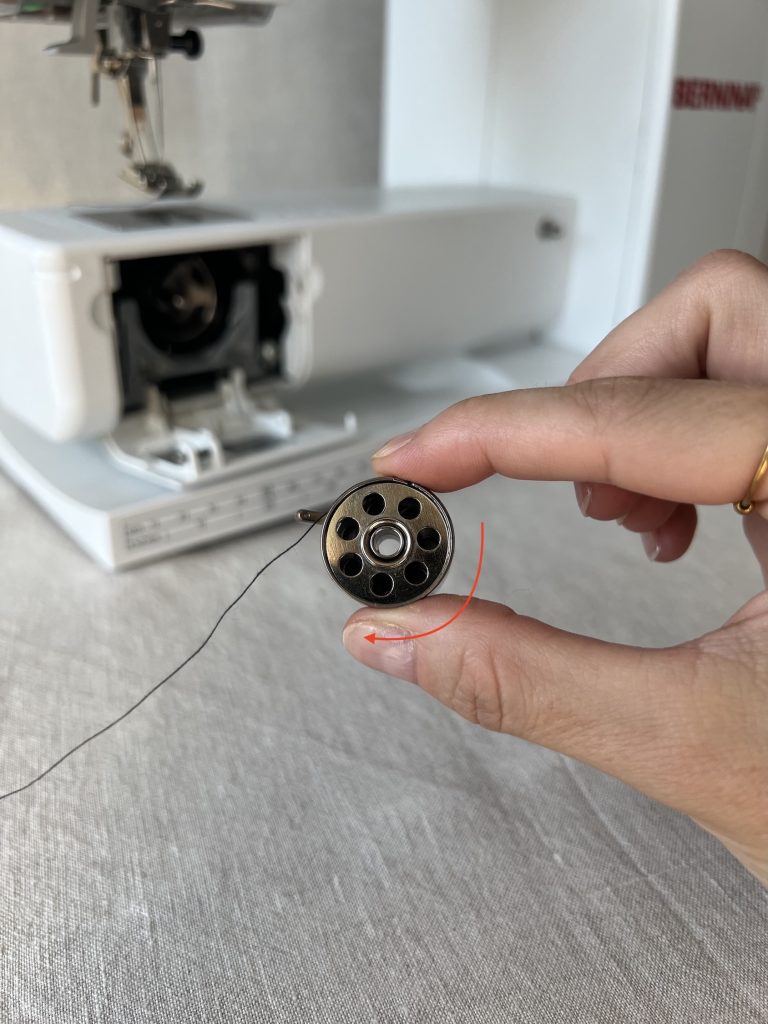

Inserting bobbin into bobbin case

1. Insert the bobbin into the bobbin case ensuring the thread spins in a clockwise direction.

2. Hold the bobbin and bobbin case and ease the thread into the slot, under the tension spring, and into the t-shape slit.

3. Pull the thread a little to double check that the thread is spinning in a clockwise direction.

Tip: If sewing buttonholes, try threading the bobbin thread through the finger of the bobbin case. This will make the tension a little tighter and hopefully create a neater button hole.

Inserting the bobbin and bobbin case into the machine

1. Raise the needle by turning the hand wheel.

2. Raise the presser foot by lifting the presser foot lifter at the back of the machine.

3. Open the bobbin cover.

4. Lift the bobbin case latch, and insert the bobbin case into the machine. Ensure the finger of the bobbin case points in an upwards direction.

5. Gently push the bobbin case into the machine until you hear a click.

6. Cut off any excess thread using the bobbin cover thread cutter.

7. Check that the bobbin case has been inserted correctly by winding the hand wheel a couple of times. The bobbin case should rotate as you do this. You will know if it has not been inserted correctly as it will simply fall out. If this is the case, just try again. If everything is okay, simply close the bobbin cover.

Bringing up the bobbin thread

1. Turn the hand wheel a couple of times to lower and raise the needle. This motion should catch the bobbin thread from below. If the bobbin thread doesn’t come up on the first try, simply turn the hand wheel a couple more times.

2. Use your fingers or a pair of tweezers to gently pull the bobbin thread up through the stitch plate.

3. Pull both the top and bobbin threads toward the back of the machine.

4. Cut off any excess thread using the rear thread cutter.

Take your time when threading your sewing machine—there’s no rush. A little patience and practice really do go a long way, and before you know it, threading will become second nature. Once you’ve threaded one machine, you’ll find it much easier to thread others too, even if the layout is a little different.

Most machines include helpful guides right on the body—like numbered paths or arrows—so be sure to use them. And finally, don’t forget your manual. It might not be the most exciting read, but it’s one of the best resources you have.

Stay tuned for Part 2, where I’ll cover some more specific processes.

Leave a comment