How to Thread an Overlocker (The Easy Way)

Overlockers (or sergers) are great for giving sewing projects a polished, professional finish. Let’s face it though, threading them can feel like a real hassle, even for the more experienced sewist.

But don’t worry, I’ve got a simple trick to make the process that little bit easier. While it’s not foolproof, it works more often than not!

Why use an overlocker?

Overlockers are invaluable for finishing fabric edges. They trim and sew the fabric at the same time, using multiple threads (usually 3 or 4) to create durable stitches that prevent fraying and reinforce seams. Whether you’re closing seams or leaving them open, the results look neat and professional.

They are also especially handy for knit fabrics and stretchy materials, because the type of stitch created moves with the fabric. And beyond functionality, overlockers can create decorative finishes to edges and hems (e.g. a rolled hem).

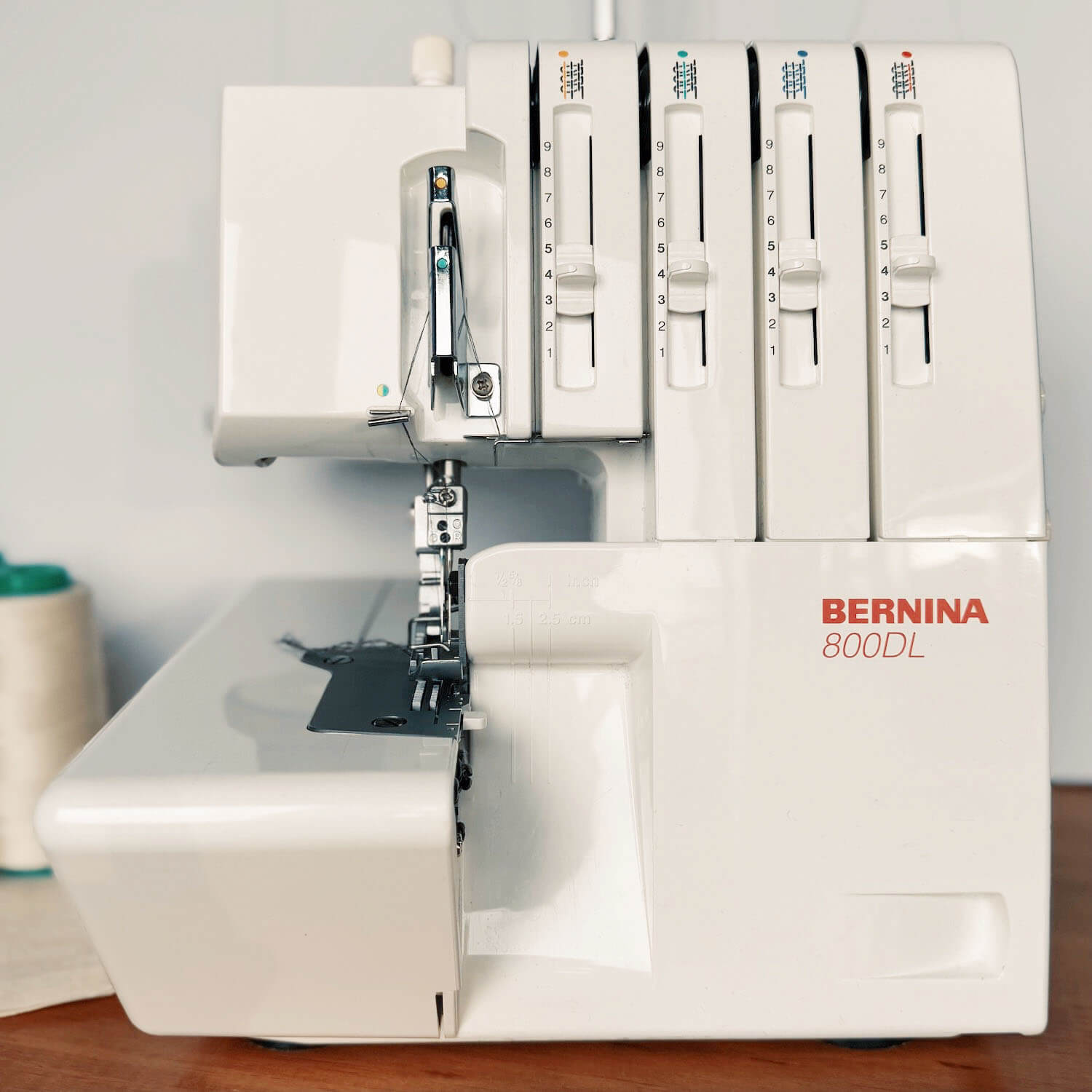

Understanding an overlocker’s parts

To get started, it’s helpful to become familiar with an overlockers key parts. Understanding these essential components will make using and threading the machine much easier. Here’s a quick guide to the key parts worth knowing:

Thread cones: Large spools of thread that are used to create the overlock stitches. These sit at the back of the machine on spool cones.

Stitch length dial: Adjusts the length of the stitch for different finishes (top dial).

Differential feed dial: Controls how the fabric feeds through the machine, helping to prevent stretching or puckering, especially on knit fabrics (middle dial).

Hand wheel: Manually raises or lowers the needles, allowing for precise positioning of the fabric and needles (bottom dial).

Thread tension sliders: For adjusting and fine-tuning the tension of each thread to ensure neat and even stitches.

Needle threads:Produce two rows of straight stitching (orange and green).

Looper threads: Interlock with the needle threads to form the overlock stitch. There is one upper (blue thread) that is visible on the right side of the fabric, and one lower (red) that is visible on the wrong side of the fabric.

Presser foot: Holds the fabric securely in place while sewing. A lever to lift and lower the foot is located at the back of the machine, just behind the foot—similar to a standard sewing machine.

Cutting blade: Trims the fabric as it is sewn, giving it a clean and neat edge.

How to thread an overlocker the easy way:

Threading your overlocker may vary depending on the machine model, but the steps are generally the same. Here’s a simple step-by-step guide, demonstrated on my Bernina 800DL:

1. Turn off the overlocker: For safety, ensure the overlocker is switched off before starting.

2. Raise all of the thread needles: Turn the hand wheel to raise the needles to their highest position.

3. Cut the existing threads: Snip the existing threads close to the cones prior to removal (this is important for step 5).

4. Replace the thread cones: Remove the existing thread cones from the spool holders and replace them with the new threads.

5. Tie on the new threads: Using a small, strong knot, tie the ends of the new threads to the old ones snipped in step 3. Give each knot a gentle tug to ensure it is secure.

6. Trim thread ends: Trim the ends of the knotted threads so they are neat. This limits the risk of them tangling or catching as they move through the machine. I recommend leaving no more than a 1-2cm tail.

7. Pull the threads through the machine: Begin by gently pulling (don’t yank) the looper threads through the machine, followed by the needle threads. You may encounter some resistance as the knots pass through. When the knots on the needle threads reach the eyes of the needles, cut the threads on either side of the knots. Finally, pull the remaining thread tails through the needle eyes.

8. Thread the needles: Manually re-thread each needle with the new threads. This step can be a bit fiddly, so using tweezers can make it easier to reach those tight spots.

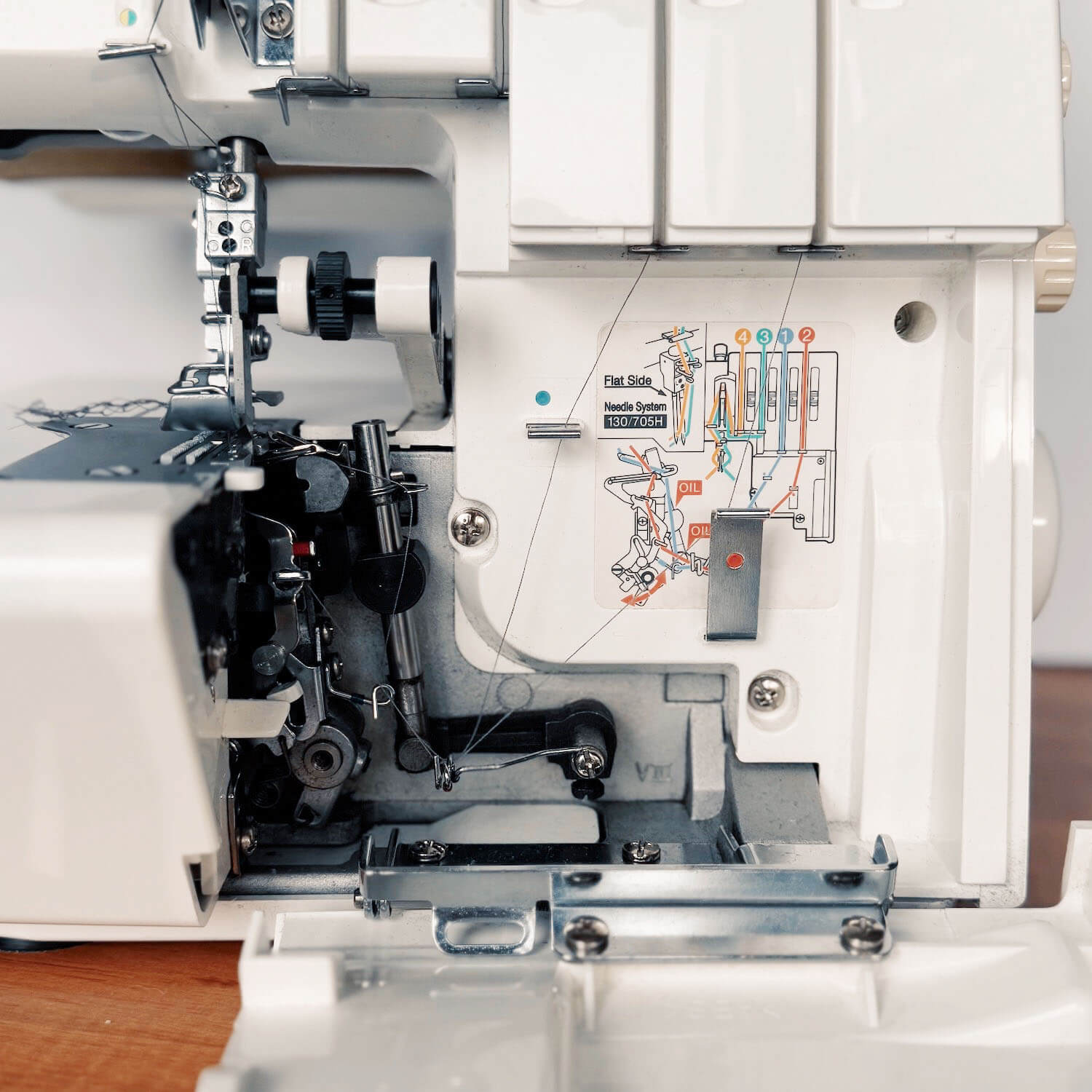

Tip: Open the looper cover of your machine so you can access the threading area. This will allow you to watch the looper threads as they move through the machine, and guide if needed, or re-tie if they come undone.

9. Test the threading: Sew a test swatch to confirm the machine is threaded correctly.

Additional Tips

Many machines have colour-coded guides within the threading area (simply open the looper door or panel) that shows the thread path for each of the threads. These guides are great for double-checking your threading.

Some machines may have additional levers you need to release in order to access certain parts of the threading area.

Many overlockers must be threaded in a specific order (e.g., lower looper, upper looper, left needle, right needle). Check your manual to avoid threading issues.

If your stitches look uneven or messy, it could be an issue with the tension. Double-check each thread’s tension dial to make sure it’s correctly set, and if in doubt check your manual.

Once you’ve successfully threaded your overlocker, I recommend taking a photo (or video) for reference. This will make troubleshooting much easier in the future. I do this to ensure my thread tension stays exactly where I want it, especially in case it changes when I move my machine.

Don’t overlook your overlocker manual—it’s an invaluable resource for troubleshooting, offering detailed instructions and helpful diagrams.

Re-threading your overlocker doesn’t have to be a pain. With a little practice, you’ll get the hang of it. Just follow the steps, use the colour guides, and take your time. Before you know it, you’ll be back to finishing those neat, professional edges.

4 Comments

Kelly Singh

I’ve have a Brother Serger i bought during the pandemic when I got back into sewing. I’ve never used it. Im afraid of it. It mocks me. I use my newer Janome Skyline for everything, but it just doesn’t do a proper, neat overlocking stitch. 2025 is the year to learn how to use the Serger. I can do it! Thank you for the reminder and dose of courage.

Emma Cartmel

Hi Kelly,

Thank you for your comment.

I totally understand! It took me some time to master my overlocker too—just a matter of practice. It’s not as tricky as it seems once you get the hang of it.

I’m excited you’re making it a goal for the new year!

Hope my article was helpful.

Pamela Boynton

I have that exact 800D. While I like the machine, and have had it for a Very Long Time, the Tie-A-Knot method often causes me more problems than if I just took everything off. Rethreading the needles is easier than catching the knot, cutting it off, and then having to rethread the needles before it stops with the knot unable to go through the eye. However, The cone you should rethread 2nd, that last cone in the line!, the one you have to take all through the bottom, and is a major pain if you have to get it through that slide, and then try to grab hold of it to get it to the eye of that arm – it really is difficult to grab hold of. That is the ONE that IF I can get the tie a know method to work, is really easier.

So I usually just leave white thread on the 800D, and change colors on My Mom’s old Simplicity. It sews just as well, and is so much easier to rethread.

Emma Cartmel

Hi Pamela,

Thanks for sharing your experience with the 800D!

I can definitely appreciate that the tie-a-knot method isn’t for everyone or every machine—as I mentioned, it’s definitely not foolproof. I’ve just found that my method works best for me, and I find it much easier than rethreading every time.