How to Select and Use Interfacing: A Simple Guide

Iron-on or sew-in, woven or non-woven, lightweight or heavyweight. With so many different types, weaves, and weights to choose from, how do you know which interfacing is best for your project?

In this article, I will explain the two main types of interfacing before diving into the differences in weave and weight. Hopefully by the end you should feel more confident when it comes to selecting interfacing for your next sewing project.

What is Interfacing?

Interfacing (sometimes called interlining) is a type of fabric that is applied to the reverse of another fabric. Its purpose is to provide stability and structure, while also reinforcing weak spots and areas prone to stretching. Therefore, interfacing is commonly used in areas such as collars, cuffs, plackets, necklines, waistbands, and for buttons and buttonholes.

Interfacing is available in two main types: iron-on and sew-in.

Iron-on Interfacing

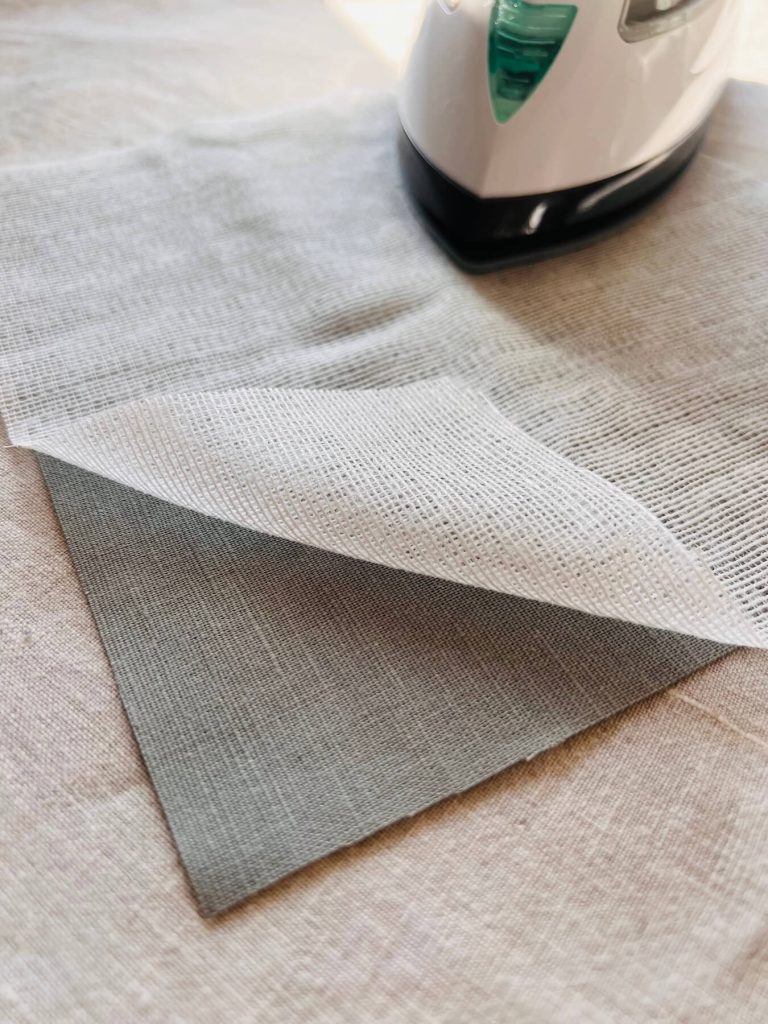

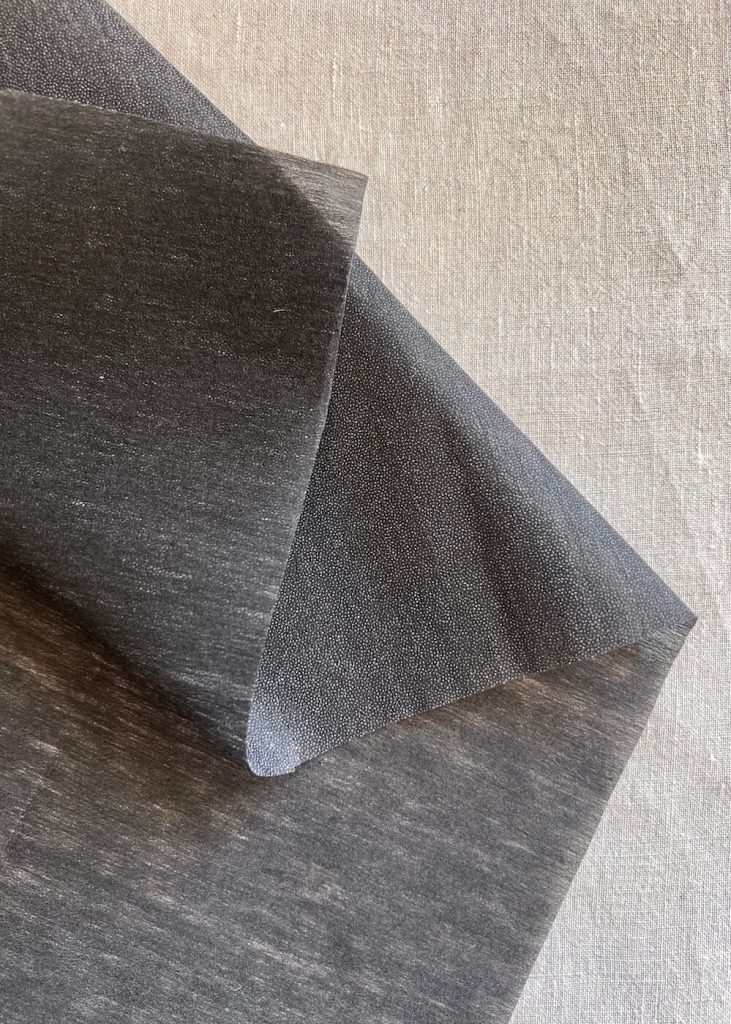

Iron-on interfacing, also known as fusible interfacing, sticks to fabric through the application of heat. On the back of iron-on interfacing, you will notice either rough dots or a shiny finish. This is the glue. When heat is applied, this adhesive layer fuses to the fabric.

Iron-on interfacing works best with fabrics that can tolerate heat, such as cotton or linen.

How to apply iron-on interfacing:

1. Cut the interfacing to match the pattern piece.

2. Lay the fabric on the ironing board, wrong side facing up.

3. Position the interfacing on top of the fabric, glue side down. Make sure the edges line up neatly and trim any overhang if necessary. Excess interfacing can stick to the iron or ironing board.

4. Cover with a pressing cloth (a tea towel also works just fine).

5. Set your iron to a dry setting (no steam) and adjust the heat accordingly to the fabric type.

6. Press the interfacing in sections, holding the iron in place for a few seconds at a time before lifting and moving to the next section. Avoid sliding the iron as this can shift and wrinkle the interfacing.

Sew-in Interfacing

As the name suggests, sew-in interfacing, also known as non-fusible interfacing, is attached to fabric by stitching.

It is ideal for projects where you want to maintain more of the fabric’s natural drape and texture, or when working with delicate fabrics like silk, or embellished fabrics that may not be able to handle the heat of an iron.

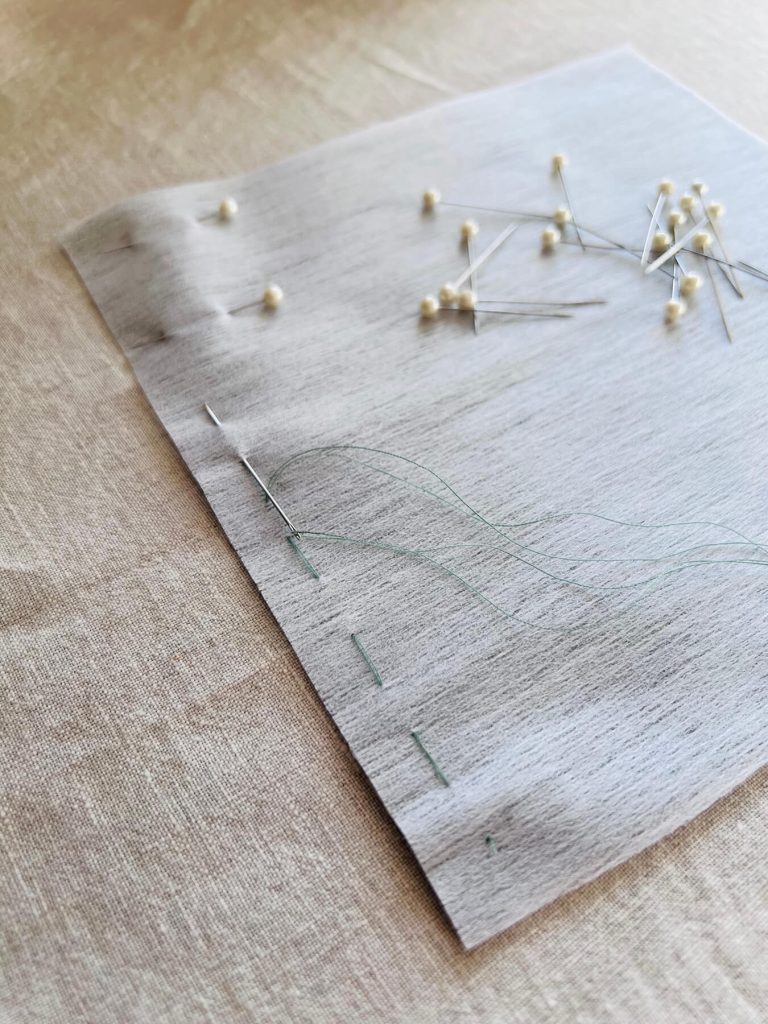

How to apply sew-in interfacing:

1. Cut the interfacing to match the pattern piece.

2. Position the interfacing on the wrong side of the fabric, aligning the edges.

Note: Sew-in interfacing typically doesn’t have a right and wrong side, unlike iron-on interfacing.

3. Pin or clip the interfacing to the fabric.

4. Baste or sew the interfacing in place to keep it from shifting while you sew. Ideally you want to stitch within the seam allowance (the area between the edge of the fabric and the stitching line).

Weaves

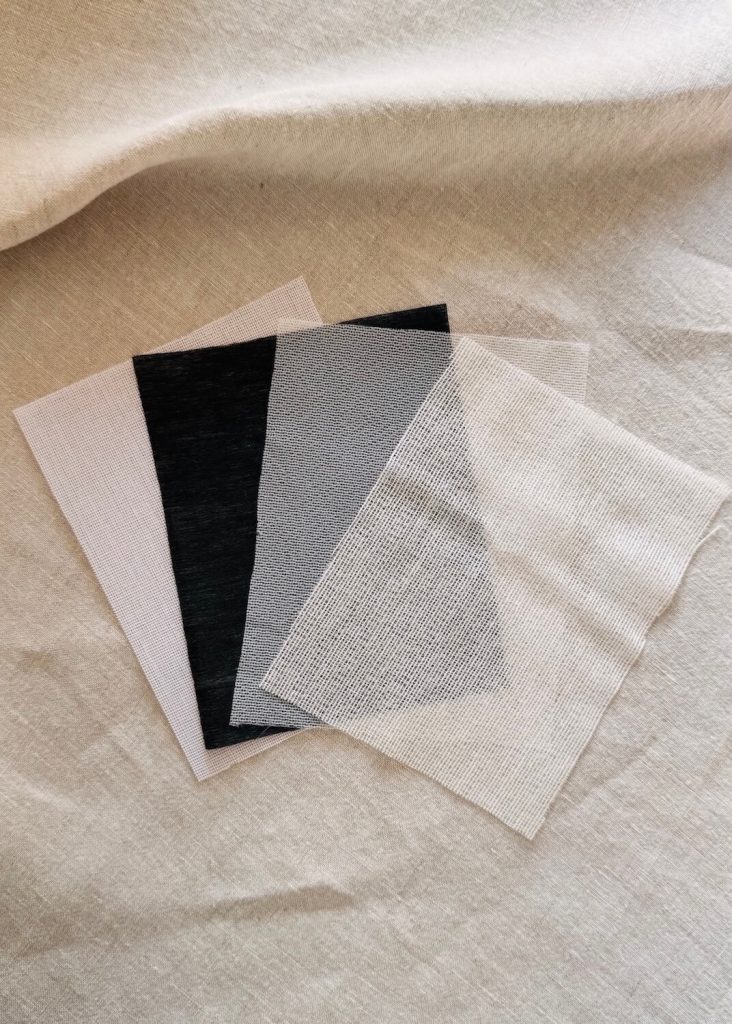

Both iron-on and sew-in interfacing can be further categorised by their weave type. The three main weaves are woven, non-woven, and knit.

- Woven: Woven interfacing is just like woven fabric, with visible warp and weft yarns. For this reason, it is a good option for woven fabrics. Since it has a grainline, it’s important to align your pattern pieces parallel to the grainline, just as you would with fabric. This ensures proper drape and strength.

- Non-woven: Non-woven interfacing is made by bonding or felting fibres together. It is less durable than woven interfacing, particularly after repeated wear and washing, and can be a little stiffer. Therefore, non-woven interfacing is better suited to craft projects, or things like accessories. Non-woven interfacing doesn’t have warp and weft yarns or a grainline. This allows you to cut pattern pieces in any direction, making it more economical and simple to use.

- Knit: Knit interfacing is made using interlocking loops, similar to knit fabric, which gives it stretch and flexibility and allows it to move with the fabric. It is therefore ideal for knit fabrics, stretchy jerseys, or lightweight woven fabrics with some drape and stretch. Before cutting, check the direction of the stretch in the interfacing and align it with the stretch of the fabric for the best results.

- Fabric as interfacing: As an alternative, lightweight fabrics like organza or cotton voile can be used as interfacing. This method is especially useful for delicate or sheer fabrics, where traditional interfacing might be too stiff, heavy or visible.

Weights

Interfacing is also available in various weights: light, medium, and heavy weight. Choosing the right weight depends on the fabric and the project needs. As a general rule, select an interfacing that matches the weight of your fabric or is slightly lighter than it.

- Lightweight: Lightweight interfacing provides subtle support while allowing the fabric to maintain its natural drape. It’s perfect for delicate fabrics like silk, lightweight cotton, or chiffon.

- Medium weight: Medium weight is the most versatile and commonly used interfacing. It offers support without sacrificing flexibility, and is suitable for fabrics like cotton and linen. This weight works well for the more structured garment details like collars, cuffs, and plackets.

- Heavyweight: Heavyweight interfacing provides a lot of stability, and is often reserved for more specialised projects like bags, hats, or items that need extra structure. While it’s less common in dressmaking, it’s useful for projects requiring a firm finish.

Tips for choosing the right interfacing for your project

There are no hard-and-fast rules for selecting interfacing. It really does depend on the project and fabric. The best advice? Test, test, test! Always try out different interfacing options on scraps of fabric to ensure the desired look and feel is achieved. However, here are some general tips to help you choose and use interfacing:

- Colour matters: Use white interfacing for light-coloured fabrics and black for darker ones to prevent it from showing through.

- Prep your fabric: Always iron your fabric first to remove wrinkles, ensuring a smooth application.

- Smooth out interfacing: If your interfacing is creased, lightly spray it with water and let it dry flat before you use it.

- Working with iron-on interfacing:

- Use a pressing motion (lift and lower) instead of sliding the iron back and forth to avoid distorting the fabric and interfacing.

- Let the fabric cool completely before sewing to ensure it bonds securely.

- Protect both your fabric and iron by using a pressing cloth.

- If working with delicate or slippery fabrics, large or particularly small and fiddly pattern pieces, it can be beneficial to interface first and cut out the pattern pieces later. This is referred to as block fusing.

- Trim to reduce bulk: For heavier fabrics, try cutting iron-on interfacing slightly smaller than your pattern piece. For sew-in interfacing, trim close to the stitching line after attaching it to reduce bulk.

- Recheck pattern markings: After applying interfacing, revisit any notches, darts, or other markings to ensure they’re still visible.

- When in doubt, ask: Check the manufacturer’s instructions or ask for advice at the store where you purchased the interfacing.

- Interfacing tape: Interfacing is also available in strips or tape form. This is a really convenient option for adding reinforcement to specific areas, including necklines, armholes, and hemlines.

The right interfacing can make a big difference to how your project looks and how well it holds up over time. Whether you go for iron-on or sew-in really just comes down to your fabric, its weight, and the kind of support you want to add.

One Comment

Lynn Tate

I have had a lot of issues with my iron on (Pellon light weight) interfacing bubbling. This has ruined many a project around the cuffs and collars. Any thoughts as to why this happens? I was my interfacing first btw.

Thanks, Lynn