Understanding Sewing Machine Needles

I’ll admit it—I’m guilty of not changing my sewing machine needles as often as I should, and I’m sure I’m not alone in this! However, I have gotten better over time, recognising just how much these small tools can impact the outcome of a sewing project.

Picking the right needle can improve stitch quality, make for a better sewing experience, and even keep your machine running smoother for longer.

In this article, I’ll walk you through the basics of sewing machine needles and hopefully help you make the best choice for your next project.

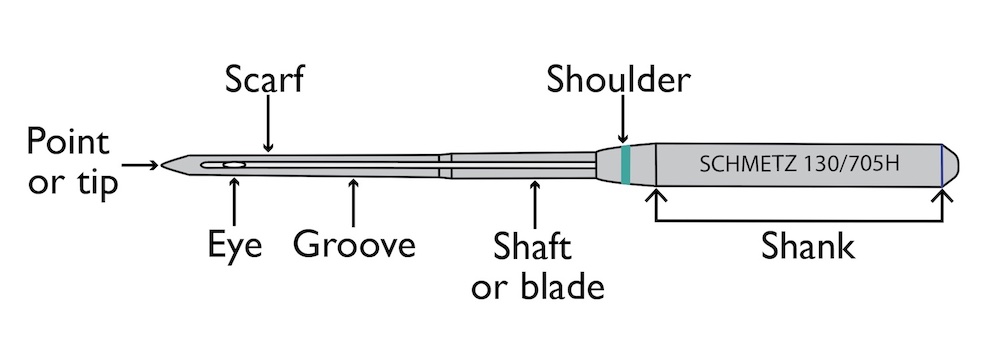

Anatomy of a sewing machine needle

Each part of the needle, from the shank to the point, plays a specific role in the sewing process. Here’s a brief overview:

Shank: The thick upper part that is inserted into the machine. Most home sewing machine needles have a flat side that faces the back. The brand and size of needle is often identified (engraved) on this part of the needle. Therefore, if you have lost the packaging you could try taking a (very) close look at this part of the needle.

Shoulder: The sloping section between the shank and the shaft. Some brands use a coloured band here for easy identification of needle type and size.

Shaft or blade: The main body that provides the needle with strength. The diameter of the shaft determines the needle size.

Groove: A small channel that guides the thread through the needles eye and into the fabric.

Scarf: The indentation at the back just above the eye. This is where the thread is grabbed by the bobbin to form stitches.

Eye: The hole near the point where the thread is inserted.

Point or tip: The end of the needle that penetrates the fabric. Different shapes and levels of sharpness suit various fabrics.

Needle types

There are various types of sewing machine needles, each designed for specific fabrics and techniques. Here are some common types:

Universal: Slightly rounded point and a medium sized eye suitable for most woven and some knit fabrics. They often come in packs of multiple sizes (e.g. 70-90).

Ballpoint or jersey: Have a rounded tip that rolls and pushes aside fibres rather than piercing them. These are perfect for heavier weight and looser knit fabrics, such as ribs and fleeces.

Stretch: Similar to ball-point but less rounded. These are recommended for use with highly elastic fabric, such as spandex and Lycra.

Sharps: As the name suggests, they are sharp and feature a strong shaft to ensure easy penetration of the fabric. They are suited for fine and tightly woven fabrics.

Denim or jean: Feature a sharp point, strong shaft, and a larger eye. As the name suggests, they are suited for heavy and densely woven fabrics like denim and canvas.

Leather: Feature a chisel-like point that easily penetrates leather or suede.

Quilting: Feature a tapered point and strong shaft for penetrating multiple layers of fabric, including wadding.

Embroidery: Feature a larger eye to allow for embroidery threads to be passed through.

Twin: needles feature two needles attached to a single shank by means of a crossbar. They create two evenly spaced rows of stitching on the right side, and a small zigzag stitch on the reverse. Theses needles provide a professional finish for both stretch and non-stretch fabrics.

Understanding needle numbers

Needle system

The sewing machine needle system uses codes to indicate type, size, and compatibility. For example, 130/705H is a universal needle suitable for most tasks. The ‘130/705’ indicates a needle with a flat shank that can be used with most home machines. The ‘H’ stands for the German word “Hohlkehle”, meaning “hollow groove”. It refers to the small indentation (or scarf) on the back of the needle.

Needle size

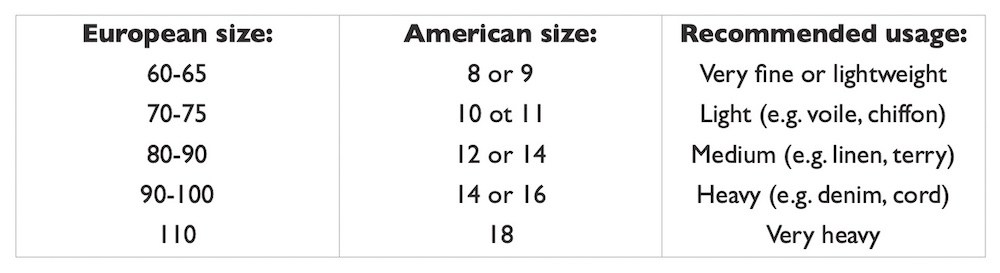

Needles within the 130/705 system come in sizes like 70/10, 80/12, 90/14, where the first is number is the European size and the second is the American. The larger the number the larger the needle, and the smaller the number the smaller the needle. Generally speaking the heavier the fabric, the bigger the needle you will probably need.

Note: Twin needles will feature two numbers. The first number is the distance between the needles, and the second number indicates the needle size.

What are the signs that you may be using the wrong sewing machine needle

Poor stitch quality

- Uneven stitches: Uneven stitches, loops, or inconsistent tension can occur when using the wrong needle type or size.

- Fabric puckering: A wrinkling effect in the fabric may be caused by a needle that is too sharp or too blunt for the fabric.

- Thread damage: Fraying threads can happen when the needle doesn’t accommodate the thread properly.

Damage to the fabric

- Snags and tears: Damage to the fabric can result from using an inappropriate needle size or point type that doesn’t penetrate the fabric properly.

Increased wear on the machine

- Bobbin case damage: An incorrect needle could damage the bobbin case and shuttle, leading to issues with the bobbin tension and stitch formation.

- Needle damage: Using the wrong needle can cause it to bend, and potentially break, damaging the machine.

- Machine timing issues: Consistent use of an unsuitable needle can affect the machine’s timing, resulting in skipped stitches and misalignment issues.

- Unusual noises: Clicking or popping sounds may indicate that the needle isn’t able to pierce the fabric smoothly.

What to remember when choosing your next sewing machine needle

The fabric weight: Consider whether the fabric is delicate, heavy, or stretch, and choose a needle that matches its characteristics. Use smaller needles for lightweight fabrics and larger needles for heavyweight fabrics to ensure proper penetration and stitch formation.

The type of thread: Determine whether you’re using regular polyester yarn or specialised threads like embroidery or metallic. Choose a needle with an appropriate eye size and shape.

Test on scrap fabric: Before starting your project, test the needle on a scrap piece of fabric to ensure it’s the right choice for the material and thread.

Change your needle regularly: Switch to a new needle at the start of every project or after approximately 10 hours of sewing. Regular changes prevent needle wear that could compromise your sewing quality.

While I’ve been guilty of overlooking the importance of changing my sewing machine needles, I’ve come to realise just how crucial they are. Understanding the potential problems caused by using the wrong needle—and knowing what factors to consider when selecting a new one—will only improve your sewing experience and hopefully help prevent unnecessary damage to both your project and your machine.

6 Comments

Baby world

What an excellent overview of needles! It’s packed with handy information and serves as a great reminder of the importance of changing needles regularly.

Emma Cartmel

Hello. Thank you so much! I’m glad you found this resource helpful.

M Leath

This is a good article. After I retread the top thread, the bobbin, and check the tensions it will usually be the needle that needs replacing. Ms. McPherson is correct changing your needle regularly is important. Thank you

Emma Cartmel

Thank you for your message! I’m glad you found the article helpful. It’s true — changing your needle regularly can make all the difference. Happy sewing!

Ellen McPherson

What an excellent overview of needles. Packed with handy information and a great reminder of the importance of changing needles!

Emma Cartmel

Hi Ellen. Thank you so much! I’m glad you found the overview helpful.